Introduction to Impact of Tariffs

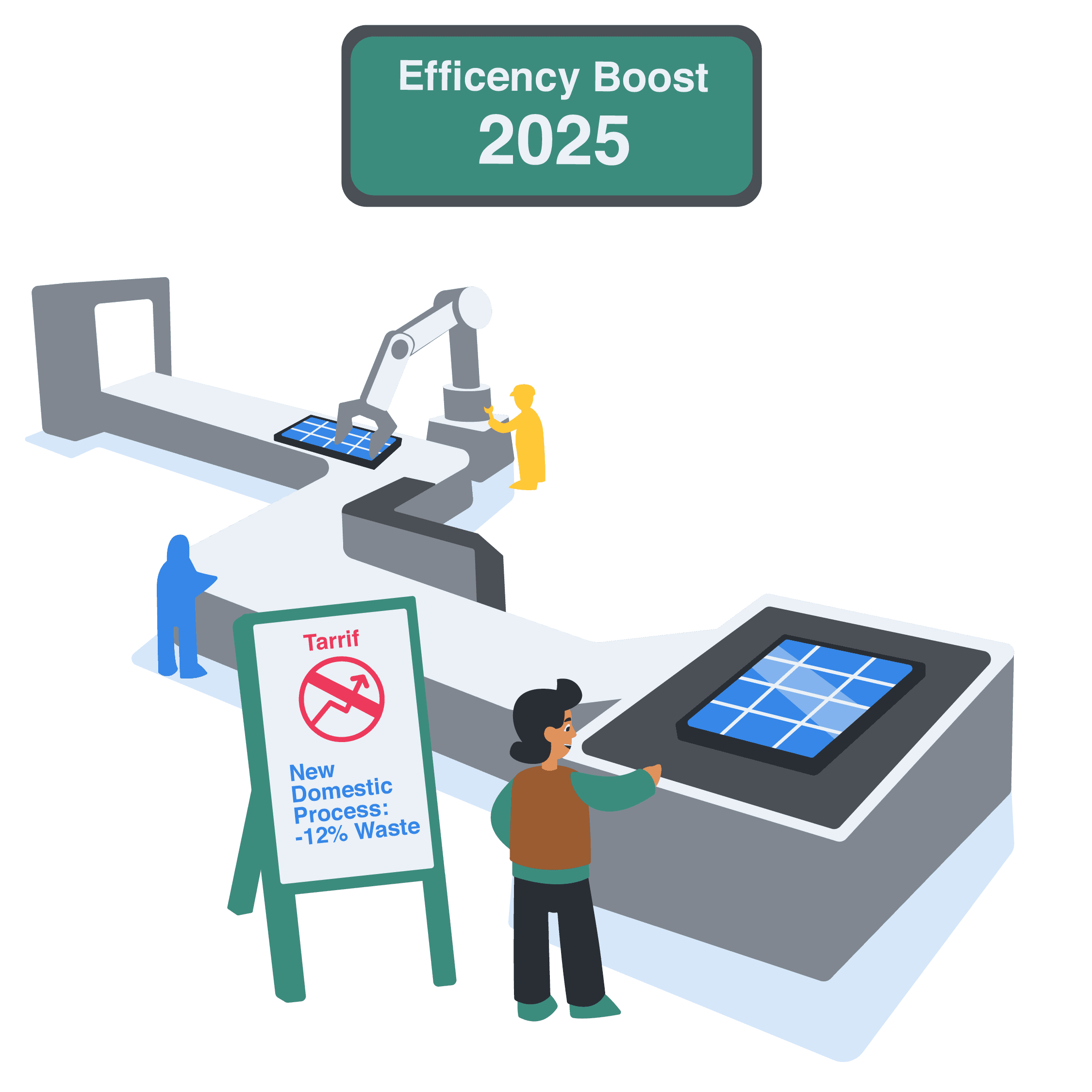

In this final lesson, you’ll explore how tariffs can influence different areas of the economy, from industries and supply chains to jobs, prices, and long-term planning.

Trade policies like tariffs may shift production costs, affect product availability, and shape business decisions around hiring and investment.

This lesson also highlights how companies of different sizes respond to such changes, using real-world strategies to manage risks and adapt to evolving trade environments.